About Us

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUCT DISPLAY

Product display

The WDG system for Agrochemical

Here is the title one h1 placeholder text

Classification:

Jet mill

Product Description

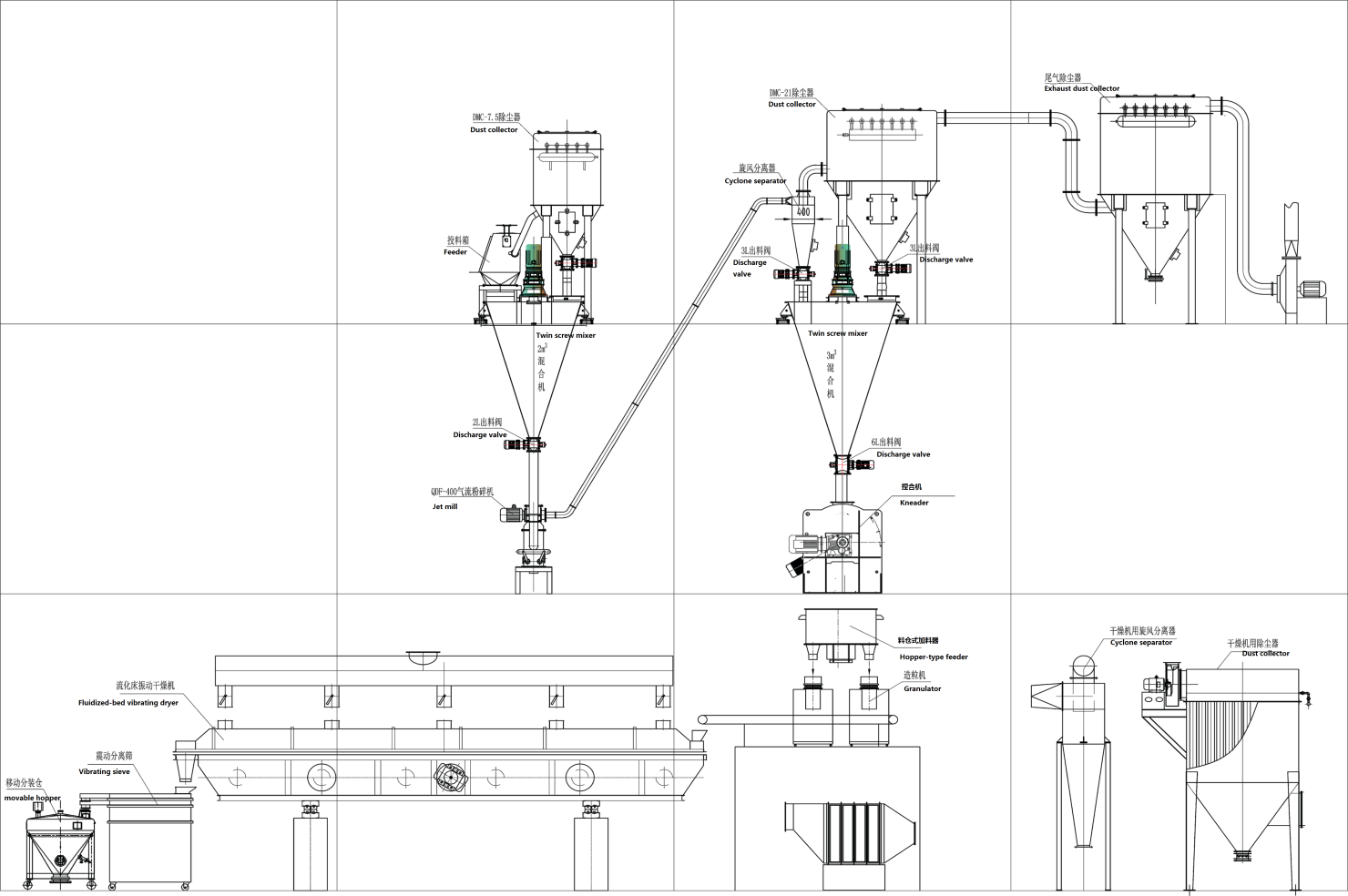

QDF-400 the process is done based on the WP

QDF-400 the process is done based on the WP

1.QDF-400 Jet mill

2.DN150 Soft Connection

3.XLF-2L Discharge Valve

4.2m3 Twin Screw Mixer

5.SQB-1 Weighing Module

6. Support Base for Feeder 7.TLX-00 Feeder

8.DN150 Double Clip Type Pneumatic Butterfly Valve

9. Bracket for Dust Collector

10. DMC-7.5 Dust Collector with Feeder

11.GT-36 Pneumatic Vibrator

12.XLF-3L Discharge Valve

13.Movable Hopper

14. Screw Feeder

15.XLF-8L Discharge Valve 16 .3m3 Twin Screw Mixer

17. . SQB-1.5 Weighing Module

18. Support Base for CycIne

19.XF-400 Cyclone Separator

20.DMC-21 Dust Collector for Grinding

21. .Second Level Dust Collector

22.Draft Fan for Second Level Dust Collector

23.Pear knife mixer

24. Kneader

25. Pelletizer

26.Cyclone Separator for Dryer 27 .dust collector

28.fluidized-bed vibrating dryer

29.vibrating sieve

30.movable Hopper 31 .draft fan for feeding

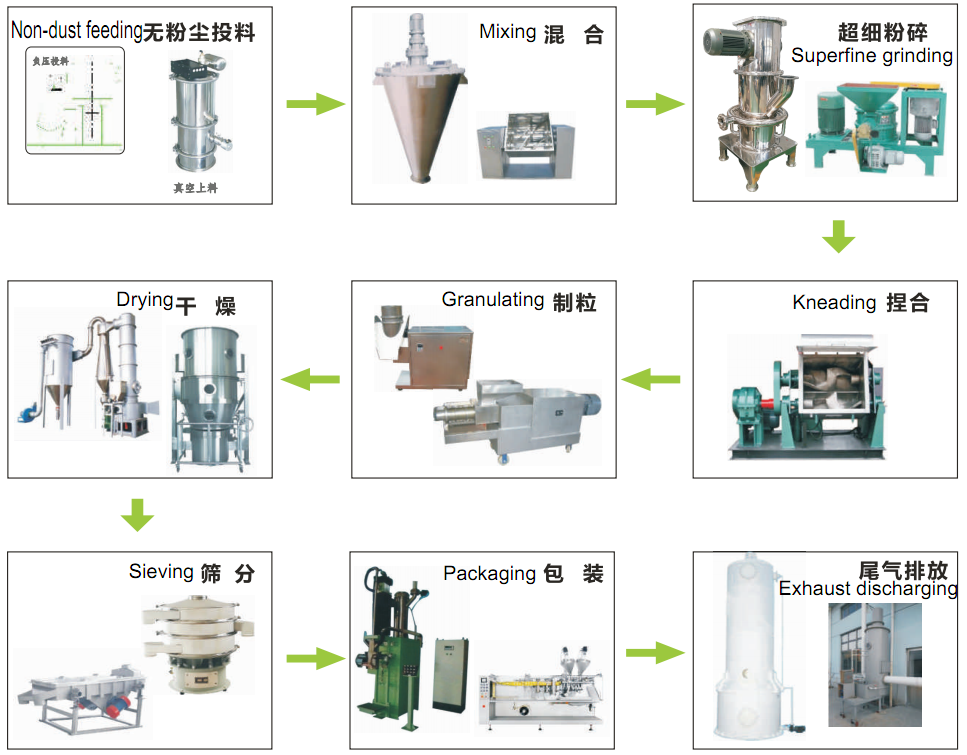

WDG (water dispersible granule) also known as wettable powder dry suspending agent or grain type, the raw material for wettable powder(WP) formed by granulation once in the water, can quickly disintegrated and dispersed, granular preparation form high suspended solid dispersion system.

Granulation is the core of the entire process. Granulator is the key to make sure granulated pesticides and drying process con-figured, which is based on thecharacteristics of pesticides, experimental data and engineering application examples, choosing rotating extrusion granulator or twin screw extrudergranulator.(Add cooling water system on drive shaft section),Or screw granulator (Add cooling water system to Granulation chamber section),Or afluidized bed granulator(Fluidized bed granulation process and extrusion granulation process is different).The requirement of moisture content of granulation is about 8- 18%. Based on product characteristics and production processes, to determine the design of the process mainly consist of :kneading,granulation, drying, screening, packaging, hot air systems, dust removal system.

| Material Name | Handness | Machine Type | Finished Product Fineness | Capacity (kg/h) |

| Ceria | 7-7.5 | QDF-400 | D50,0.8μm,D100,5μm | 50-60 |

| WC (Wolfram Carbide) | 8.5-9 | QDF-400 | D100,3.8μm | 70 |

| Sic (Silicon Carbide) | 9.5 | QDF-300 | D97,1.17μm | 40 |

| SiN (Silicon Nitride) | 9-9.5 | QDF-400 | D50,2.5μm | 20 |

| TiB2 | 9-9.3 | QDF-400 | D50,5.3μm | 45 |

| SiO2(Glass powder) | 7.8 | QDF-300 | D100,20μm | 70 |

| AL2O3(Ceramic Powder) | 9 | QDF-400 | D97,2.07μm | 30 |

| ZrO2 | 7.5 | QDF-400 | D50,3.7μm | 25 |