About Us

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUCT DISPLAY

Product display

Disc type(Ultrasonic/Pancake)Jet Mill

Here is the title one h1 placeholder text

Classification:

Jet mill

Product Description

PRINCIPLE

Disc type(Ultrasonic/Pancake)Jet Mill. The Operating Principle: Driven by compressed air through feeding injectors,raw material is accelerated to ultrasonic speed and injected into milling chamber in tangential direction, collided and grinded into particle. The particle size can be controlled by adjusting longitudinal depth, milling pressure and material feeding speed. Disc type Jet Mill do good performance to gummy materials.

FEATURES

1.Suitable for the dry-type superfine process, highest impacting speed up to 2.5 March and normally 1一10um grains.

2.Good performance to gummy materials without any block.

3.No temperature rise, suitable for low-melting and heat- sensitive materials.

4.Advantages: simplified design, easy to clean and maintenance, low noise, vibrationless.

APPLICATION SCOPE

It is widely applied to superfine milling in such fields as pesticide, chemical smelt and pharmaceutical industries. For carbendazim. formal topsin, herbicide, silica aero gel,

pigment dye and cortisone.

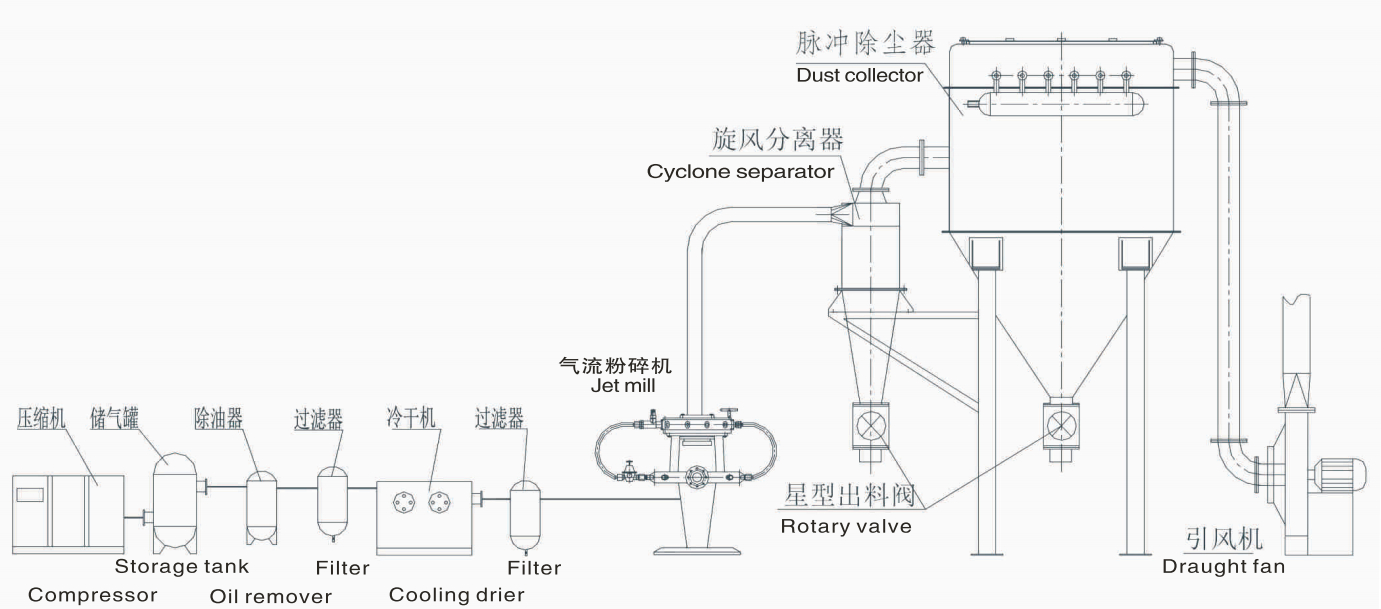

Flow chart of Disc type Jet mill

The flow chart is standard milling processing,and can be adjusted for customers.

|

Parameter/ Model

|

QDB-200 | QDB-300 | QDB-400 | QDB-600 |

| Capacity(kg/h) | 0.2-30 | 30~260 | 80~450 | 200~600 |

| Air Consumption(m³ /min) | 2 | 6 | 10 | 20 |

| Working Pressure(Mpa) | 0.75-0.85 | 0. 75~0.85 | 0.75~0.85 | 0. 75~0.85 |

| Feed Diameter(Order) | 60-325 | 60~325 | 60~325 | 60~325 |

| GrInding Size(μm) | 0.5-30 | 0. 5~30 | 0. 5~30 | 0. 5~30 |

| Energy Consumption Power(kw) | 20 | 55 | 88 | 180 |