About Us

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUCT DISPLAY

Product display

The Jet milling and mixing system for Agrochemical(WP)

Here is the title one h1 placeholder text

Classification:

Jet mill

Product Description

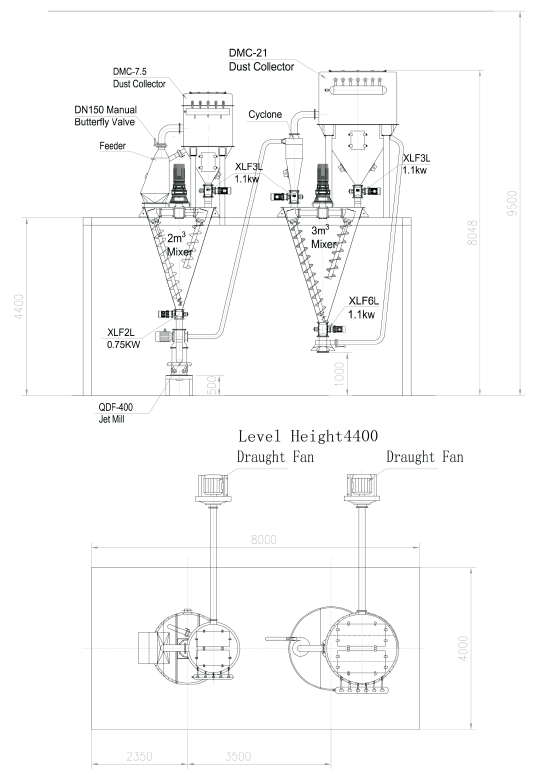

Jet Mill System--Apply to Agrochemical flow scheme

This system is a perfect combination of jet mill technology, mixing technology and intelligent control technology. which is a satisfying product for pesticides to multi一mix and remix,Meanwhile,it meets environmental request that no dust during the whole process.

We have more than 10 technical talents who have been engaged in the system design for more than 20 years in the powder industry and have rich experience in pulverizing,mixing,drying,pelletizing,packaging,and powder conveying. in Agrochemical一WP/WDG production lines,We can design the flowchart according to clients' requirements to meet customer's crushing requirements for various materials.

FEATURES

1.The milling process is applying the fluidized-bed jet mill working principle with high efficiency, and the particle size distribution is uniform.

2.The feeding process is with the minus pressure air transportation, the exhauster is added to prevent the dust emanation.

3.Both the first and last mixing process are applying the double screw mixers or horizontal spiral ribbon blender which insure the mixing is sufficient and symmetrical.

4.The product outlet can directly connect to the auto packing machine.

5.The whole system is controlled with the remote PLC control.

Strict technics Quality first Pursuit of excellence Customers' satisfaction

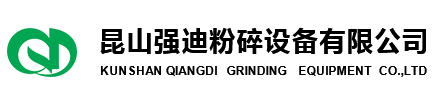

Continuous model,Applied to mass production

(QDF-400 Recommended product for agrochemical industry)

( QDF-400推荐的生产流程图)

1 .Pipeline connection between dust collector and finished products outlet prevent dust leaking out, realize no dust packaging and no contamination.

2.Twin screw mixer has long stirrer and screw design,which keep completely mixing material from settling down under the action of the revolution and rotation.

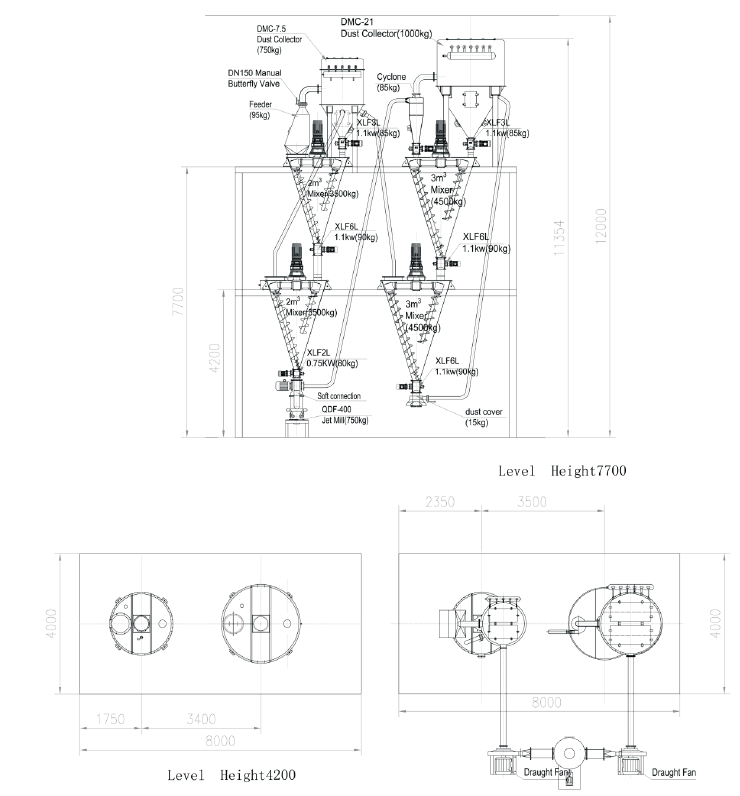

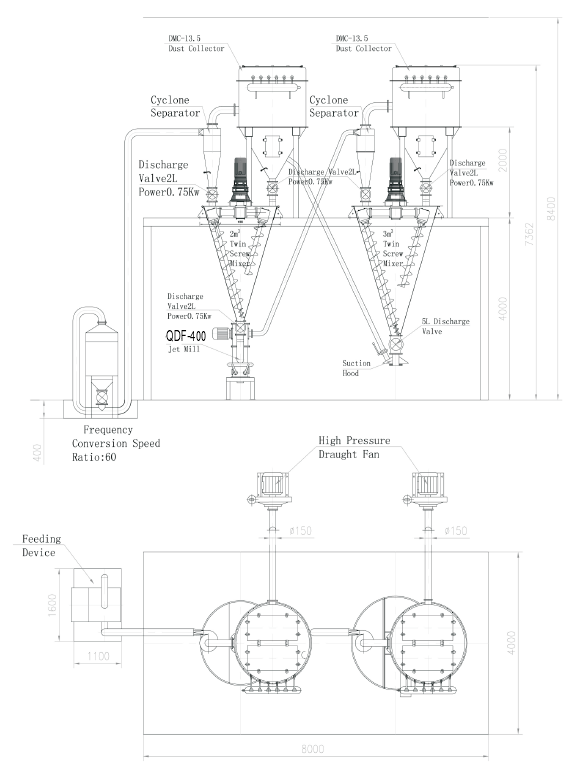

Continuous model, Applied to mass production

(QDF-400 Horizontal spiral ribbon mixer design)

1 .Raw material hopper has mixing rod design, and the screw is enough long till the bottom to keep material flow smoothly.

2.Horizontal spiral ribbon mixer advantage: It is more convenient to make certain products which needs to add adjuvant or other chemicals at the finished product. And the mixing is much better and more accurate than the twin screw mixer. lower body height than Twin screw mixer, easy to install.

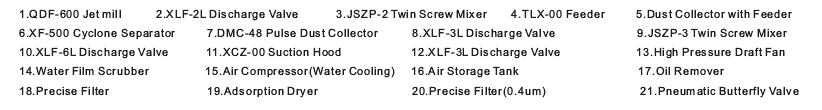

Continuous model,Applied to mass production

(QDF-600 Twin screw mixer design)

Advantage: Both the first and last mixing process are applying the double screw agitators which ensure the mixing is sufficient and symmetrical. The conical design keep the material flowing down smoothly.

Simplified model, Applied to batch production

(QDF-400 Upper feeding mode)

Cyclone separator and Dust collector: Add vibration meter to the cone part to avoid accumulation of material.

Simplified model, Applied to batch production

(QDF-400 Bottom feeding mode)

Cyclone separator: Add one more cyclone separator after the feeder to disperse raw material flow direction and avoid accumulation of material.