About Us

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

PRODUCT DISPLAY

Product display

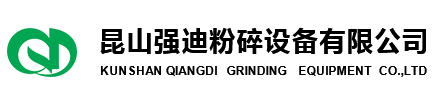

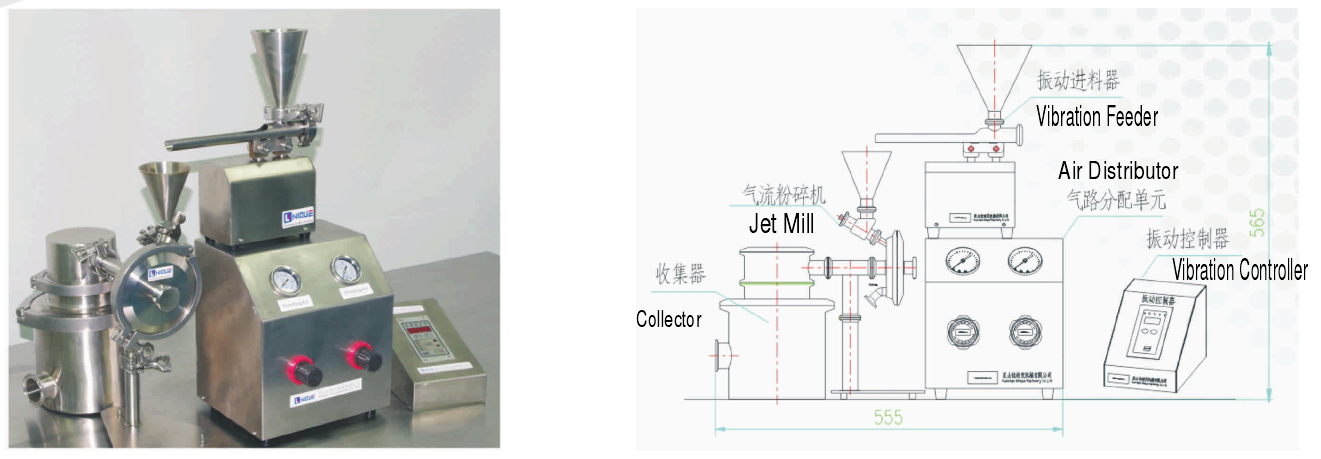

Laboratory disc jet mill

Here is the title one h1 placeholder text

Classification:

Jet mill

Product Description

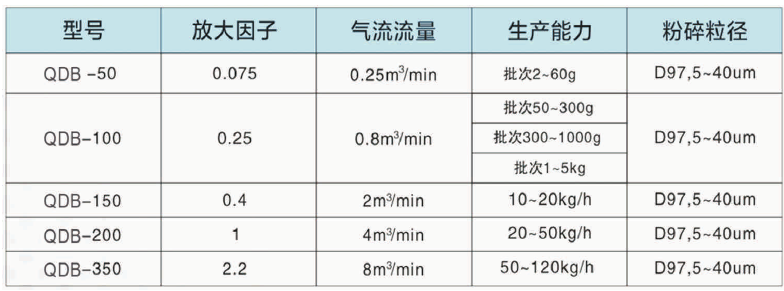

The QDB-50 laboratory air flow mill is a machine specially developed for processing small batches of pharmaceutical products. It is suitable for the research and development of new products and small trials in the pharmaceutical industry, especially for some expensive and high value-added drugs. The 50-type equipment is very suitable.

Its crushing performance is the same as that of large equipment. The particle size of the material after crushing can reach 5-40 um

Depending on the different designs of the collection device, the minimum batch size of QDB-50 can reach 2g

QDB-100 laboratory disc air flow mill

Qiangdi QDB-100 laboratory air flow mill takes into account the needs of pharmaceutical companies' laboratory micro-experiments and production departments for small batches. It adopts a desktop design, which can achieve the purpose of 50}300g batch styles. In addition, by changing the design of the collection device, it can achieve process switching with 300-1000g/batch and 3-5kg/batch, solving the contradiction of using different machine models for experiments and micro-production.

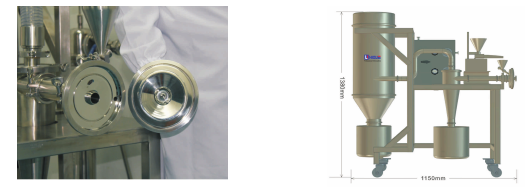

Working Principle

The grinding principle of the laboratory airflow mill is based on the fluidized bed airflow grinding principle. It uses high-speed airflow to achieve ultra-fine grinding of dry materials. The material is accelerated in the high-speed airflow and repeatedly impacts and collides at the intersection of the nozzle to achieve the grinding effect. The crushed material is graded by the classification wheel, and the material that does not meet the separation requirements continues to return to the grinding chamber for grinding until it meets the requirements. It is then collected by the cyclone separator and dust collector.

Features

1. Small output, 0.5-10kg per hour is enough, and the less material that can be crushed at one time, the better. Users hope that adding about 300kg at a time can also achieve good crushing results;

2. Easy to clean, easy to disassemble, easy to install, no dead corners inside the equipment, and no contamination to the sample due to residue during use;

3. When the equipment is crushed, the noise is low, no temperature rises, no impurities are added, and the loss is extremely low;

4. Small footprint, small size, simple and beautiful appearance;

5. Good airtightness, no dust, no unnecessary loss of samples;

6. For materials of ordinary properties, it can be crushed to about 1000 mesh in one time.

Scope of application

The machine is widely used for ultra-fine grinding of dry powder materials such as western medicine, traditional Chinese medicine, pesticides, chemicals, metallurgy, etc. in laboratory samples.

Next